Liquid Sensors

AST’s liquid sensors often combine several measurement principles into one sensor. For example, fill level measurement is often combined with a measurement of the concentration/quality of the liquid. In the case of fill level measurement, the technologies used range from ultrasound to capacitive systems that take readings from the outside through the reservoire wall to hydrostatic pressure measurement. The most suitable measuring principle is selected on the basis of customer requirements and the respective available installation space.

For concentration/quality measurement, thermal conductivity is often measured in addition to using ultrasonic systems. Sensors based on the tuning fork principle not only offer high-precision density measurement, but also allow the viscosity of the medium to be measured. The measurement of resistive and capacitive properties of liquids rounds out the technology portfolio. Concentration measurement is used, for example, in determining the ethanol concentration of the washer liquid in the washer tank and in exhaust aftertreatment with AdBlue® (measurement of urea concentration).

All AST sensors are equipped with a microcontroller and are therefore able to execute complex algorithms directly on the sensor. An output signal processed in this way is then made available in analog or digital form.

Clear Vision Sensors

Manual and autonomous driving alike are only possible if both the driver and the visual assistance systems have a clear view.

Especially in the case of poor weather conditions, this can only be ensured if there is sufficient liquid in the corresponding cleaning system and if the liquid does not freeze during the journey.

The AST sensors measure the fluid level and the temperature in the liquid tank as well as the antifreeze (ethanol/methanol) concentration. This enables the driver to top up in good time and travel with confidence.

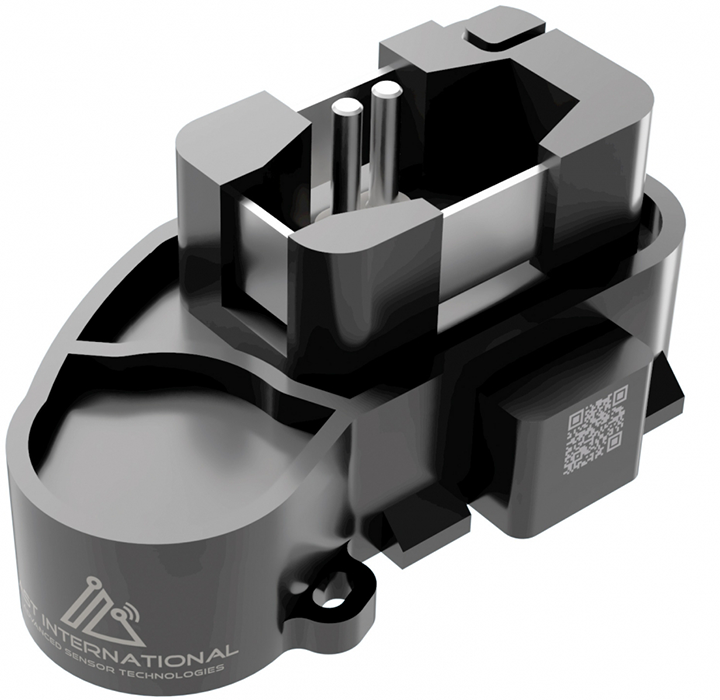

Battery Coolant Fluid Sensor

Property monitoring of the coolant Liquid used for direct cooling of High Performance EV batteries is an essential task for the safe operation of the vehicle. Especially the isolation resistance of the Liquid is a critical parameter but also the information about the degrading of other parameters will help to define the optimum time for maintenance. AST’s BCF-Sensor is able to determine the isolation resistance and the relative dielectric constant of the liquid. This multi-dimensional approach gives an outstanding performance in terms of accuracy and reliability of the measurement.

AdBlue®/ SCR-Sensors

In diesel vehicles, exhaust gas treatment with AdBlue® reduces nitrogen oxide (NOx) emissions by up to 90 percent. However, engines equipped with this technology only run if the tank contains sufficient AdBlue® fluid of the required quality.

AST sensors monitor the fluid level in the AdBlue® tank so that the driver can top up the fluid in good time. The sensors also measure the quality of the AdBlue® fluid, which features a mixture of urea (32.5%) and demineralized water.

This ensures compliance with the statutory requirements and prevents any potential improper use.

Water Injection Sensors

Water injection is a temperature reduction process for internal combustion engines, boosting performance while also reducing fuel consumption and emissions.

In order to prevent damage to the engine, it must be ensured at all times that sufficient demineralized water and no foreign liquids such as gasoline or windshield wiper liquid are present in the water tank.

The AST sensors detect foreign liquids via a conductivity measurement (based on an additional measured variable), as distilled water is non-conductive. Other non-conductive liquids are also safely detected.

Multi-Measurement-Sensor

Property monitoring of liquids used for hydraulics or lubrication is an important task for cost efficient preventive maintenance on vehicles. In-line determination of parameters providing information on degrading of oils and lubricants will help to define the optimum time for maintenance.

AST’s Multi-Measurement-Sensor can determine density and viscosity of the liquid as well as isolation resistance and relative dielectric constant. This multi-dimensional approach gives an outstanding performance in terms of accuracy and reliability of the measurement.