Current/Voltage Sensors

AST’s current sensors are based on indirect current measurement using a 3D Hall ASIC specially developed by AST for this task. This involves measuring the magnetic field created by the current in a conductor with extreme precision. This measuring method reveals its strengths particularly at high currents (>500A), since, in contrast to shunt-based systems, no additional power loss occurs at the sensing element. The shape of the current-carrying conductor can be adapted within wide limits to the respective application’s installation space and measuring range requirements. Current is measured under complete galvanic isolation made possible by the principle of magnetism. Voltage measurements are also galvanically isolated. In this case, isolation is achieved via an isolated digital interface that supports high sampling rates so that even dynamic signals can be captured reliably. Current/voltage sensors are primarily used in the powertrain of battery-electric and fuel cell-based vehicle drive systems as well as the corresponding offboard charging infrastructure. These sensors are also available in a calibratable version. The application-specific sensors’ current measurement range extends up to 2500A and therefore supports future generations of fast-charging stations.

DC METER (compliant with calibration law)

Based on the AST owned 3D-Hall ASIC technology the challenging task for a continuous measurement of 1.000A and 1.000V is ensured. This high measuring range qualifies our DC Meter especially for the use in fast and ultra charging stations as well as Megawatt chargers for buses and trucks.

The AST DC Meter is compliant with the German Eichrecht (MessEG and MessEV) and MID approved. Even with a permanent load of 1.000A and 1.000V the AST DC Meter meets the required measurement accuracy of class 1 regulated in the IEC 62053-41:2021.

In order to take future trends in the charging infrastructure into account at an early stage, the DC Meter is already designed for bi-directional charging processes.

The DC Meter is available in two design variants – as a compact measuring unit with integrated display or as a version with a remote display and greater flexibility in complex installation situations.

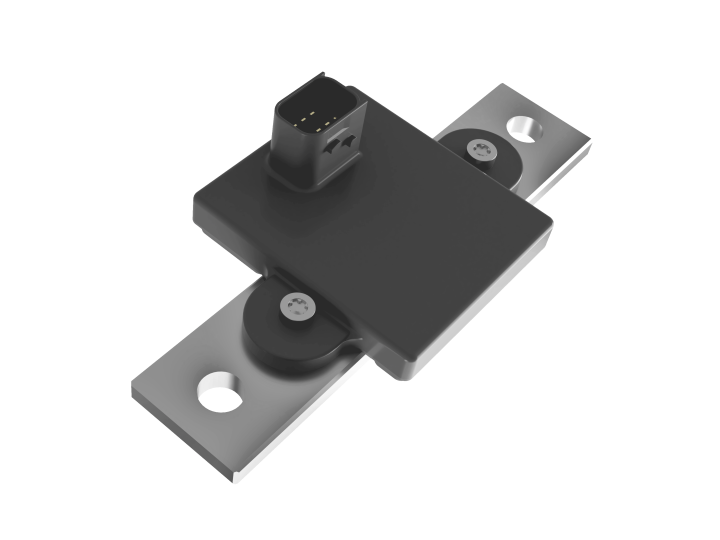

High Current / High Voltage Sensor

The AST HC/HV Sensor can be used for the measurement of current, voltage and temperature in the powertrain main rail, at the output of the charging connectors and in battery modules.

The AST sensor technology enables a contactless current measurement without introducing additional resistance (shunt) to the current path and without using flux guiding elements made of ferromagnetic materials which cause hysteresis problems. This stable measuring system guarantees a very low rise of temperature and power dissipation.

The voltage measurement is based on an insulated high speed digital interface, allowing fast sampling rates for the measurement of high dynamic signals.

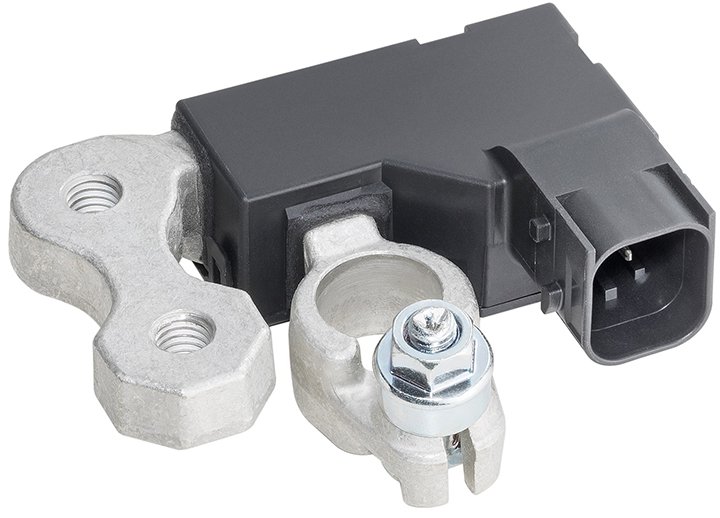

Battery sensors

Increasing electrification of vehicles has led to increasing demands being placed on vehicle batteries. Our high-precision contactless battery sensors determine the current, voltage, temperature, and status of starter batteries, providing information on aging effects and precise predictions of the remaining service life and performance capacity.

This helps prevent breakdowns due to drained batteries, with drivers knowing exactly when a battery needs to be replaced.

Our contactless measurement procedure offers a range of benefits: Not only is it permanently available, it can be flawlessly combined with start-stop functions and additional emissions-reducing measures.