Industry

Sensor technology is also playing an increasingly important role in the market for industrial applications, for example in the implementation of smart home applications. But it also enables significantly improved user-friendliness, helps save energy, and conserves resources. In this context, measured values such as level, pressure, temperature, and the detection of movements are becoming increasingly important.

Among other applications, our high-precision position sensors can be used to measure the position of grippers on robots. With our specialized liquid sensors, we are able to precisely determine the qualities, mixing ratios and condition of liquids and thus control processes for further use.

Multi-Measurement-Sensor

Property monitoring of liquids used for hydraulics or lubrication is an important task for cost efficient preventive maintenance on vehicles. In-line determination of parameters providing information on degrading of oils and lubricants will help to define the optimum time for maintenance.

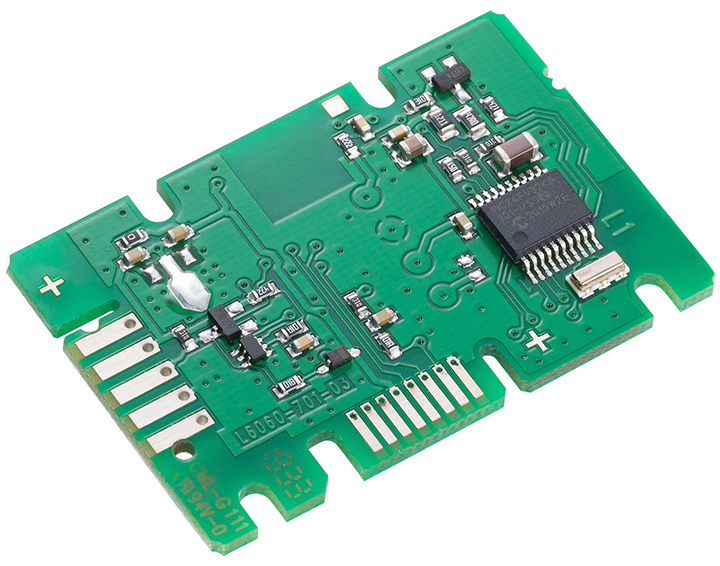

AST’s Multi-Measurement-Sensor can determine density and viscosity of the liquid as well as isolation resistance and relative dielectric constant. This multi-dimensional approach gives an outstanding performance in terms of accuracy and reliability of the measurement.

Air quality sensor

Air quality sensors permanently measure the intensity, degree of pollution, and number of odor molecules in the exhaust air. These measurements can then be used to adjust the fan performance levels and generate a pleasantly fresh atmosphere.

In addition, the continuous measurement of air pollution enables our smart sensors to predict when the filters will need to be replaced and when the unit will next require servicing.

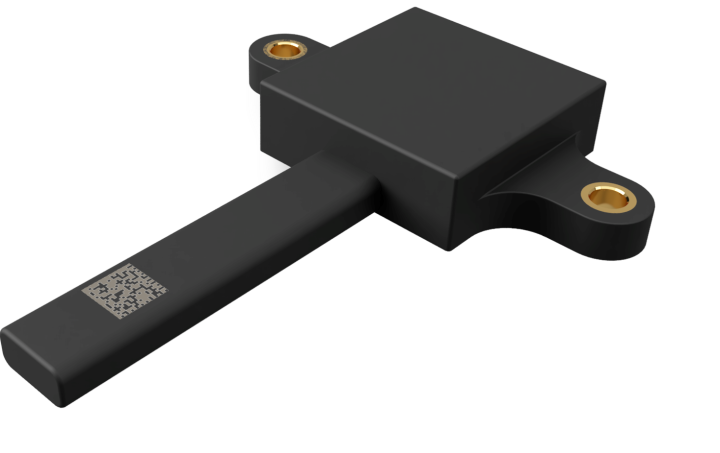

Inductive position sensor

Our position sensors with the inductive measuring principle determine the position of mechanical components without contact and without wear. The so-called target is attached to the moving part of the mechanism and interacts without contact with the stationary sensor system via inductive mechanisms. The sensor and target are each encapsulated against environmental influences, which enables operation in harsh environments.

For example, the position of clutches, dampers and hydraulic cylinders can be measured.

Imbalance sensor

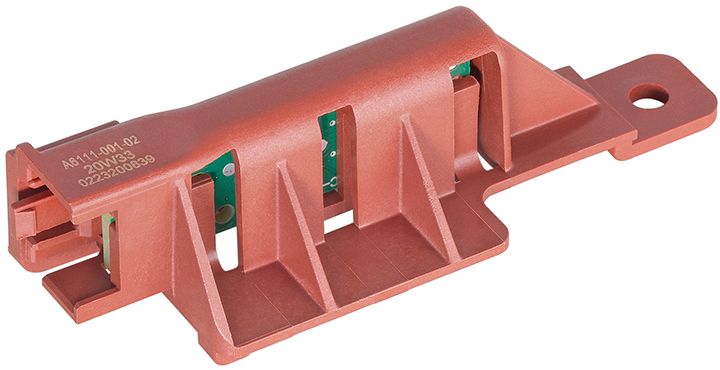

Imbalance can occur in a number of ways, such as when washing is not properly distributed within a washing machine. It may be due to a particular item soaking up an excessive amount of water or several items becoming entangled. While this does not have any negative impact during the normal wash cycle, the powerful forces generated during the spin cycle can prove problematic. As a result, nearly all washing machines now feature an imbalance monitor to prevent damage to the appliance.

Our sensors permanently monitor the weight distribution and the movement of the drum, with the appliance control system evaluating the data and adjusting the speed accordingly. A smart algorithm is then used to redistribute the washing in accordance with the load and thereby resolve the imbalance in the drum.

Force- & Torque-Sensor

AST‘s inductive Force-& Torque sensors make it possible to use structural components to measure forces and torques. The acting forces and torques lead to minimal deformations of the structure, which can be precisely detected by the sensitive sensors. The measuring principle is based on eddy currents and can detect changes in geometry in the nanometer range. The sensor electronic can be integrated into the sensor element or can be connected via a cable. Especially in high temperature environments it makes sense, to keep the electronic box separated.