Energy-Infrastructure

Especially in today's world, the provision of energy is becoming more and more important. What used to be “fuel” in the form of petrol or diesel is now being expanded to electricity and other energy carriers (e.g. hydrogen). This constantly challenges the infrastructure and is calling for technological solutions that meet the new requirements.

The sensor solutions from AST play an important role here. Our hydrogen leakage sensor system is an important safety feature in hydrogen filling stations, as it can detect even the smallest concentrations of the highly flammable hydrogen gas in the ambient air and indicate possible defects.

AST also ensures safety and transparency with its calibration law-compliant energy meter in the area of the fast charging infrastructure. Our meters not only meet the legal requirements, but above all protect the consumer from manipulation and incorrect billing. In addition, our high-current sensors are already designed for future requirements in the field of megawatt charging, making our customers fit for the future.

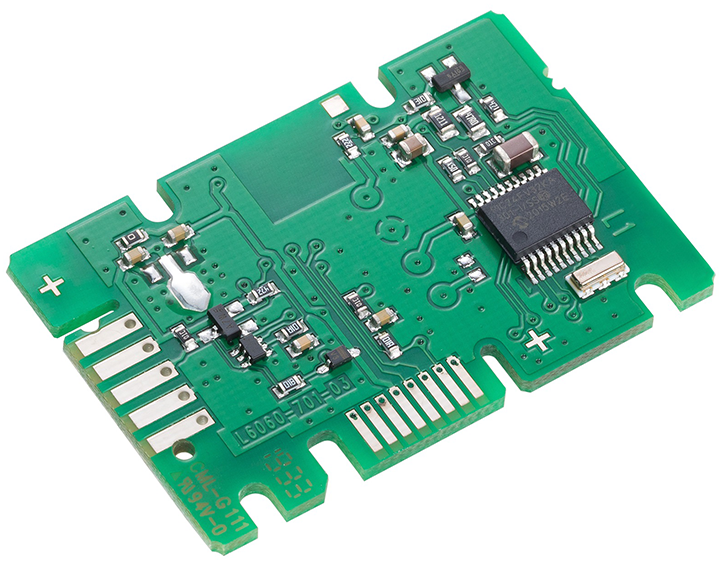

DC METER (compliant with calibration law)

Based on the AST owned 3D-Hall ASIC technology the challenging task for a continuous measurement of 1.000A and 1.000V is ensured. This high measuring range qualifies our DC Meter especially for the use in fast and ultra charging stations as well as Megawatt chargers for buses and trucks.

The AST DC Meter is compliant with the German Eichrecht (MessEG and MessEV) and MID approved. Even with a permanent load of 1.000A and 1.000V the AST DC Meter meets the required measurement accuracy of class 1 regulated in the IEC 62053-41:2021.

In order to take future trends in the charging infrastructure into account at an early stage, the DC Meter is already designed for bi-directional charging processes.

The DC Meter is available in two design variants – as a compact measuring unit with integrated display or as a version with a remote display and greater flexibility in complex installation situations.

Hydrogen Sensors

Vehicles with hydrogen drives require a safety concept at the highest level. In particular, the detection of a leak in the hydrogen supply is an essential element in the careful handling of the critical medium hydrogen. The Hydrogen sensor based on the TCS process with its robust measuring principle fulfills this requirement perfectly. It is characterized by its low cross-sensitivity to other gases and its long-term stability.

Air quality sensor

Air quality sensors permanently measure the intensity, degree of pollution, and number of odor molecules in the exhaust air. These measurements can then be used to adjust the fan performance levels and generate a pleasantly fresh atmosphere.

In addition, the continuous measurement of air pollution enables our smart sensors to predict when the filters will need to be replaced and when the unit will next require servicing.